| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 20 Days |

Model No.: TPHD2016

This machine is the automatic special equipment used for drilling, tapping, milling steel plate, flanges, tube sheets, mainly in the field of steel structure, boiler, heat-exchanger and so on. This machine also can drill through hole, blind hole, ladder hole.

Product Feature:

1. CNC slide way drilling spindle (Z axis) with work piece of stroke is pre-set, realized auto switch.

2. It can drill not only through-hole, but also blind-hole with high efficiency, simple-structure, low-cost maintenance, easy operation etc.

3. There are 12 hydraulic clamps & T slots for fixing work pieces, easy to operate, also save time, improve production efficiency.

4. This machine have three CNC axis: gantry moving direction (x-axis);drilling head moving direction (y-axis); Spindle feeding direction (z axis). Machine equip each axis with linear guide and ball screw which drived by high precision servo motor.

5. Machine have scrap cleaner which collect iron scraps and cutting liquid.

6. The machine equipped with automatic lubrication system for linear guides and ball screws.

7. Machine adopts SIEMENS 808D system, also equip with computer for drawing and workpiece program processing, easy to operate.

8. The configuration of the machine, like ball screws, linear guides, main electrical parts, servo motors, inverter, etc., all famous brands.

| Model | TPHD1616 | TPHD2016 |

| Max work piece size (L×W) | 1600x1600mm plate or Φ1600mm flange | 2000x1600mm plate or Φ1600mm flange |

| Thickness of work piece | 6--120mm | 6--120mm |

| Drill unit type | sliding table, servo control | sliding table, servo control |

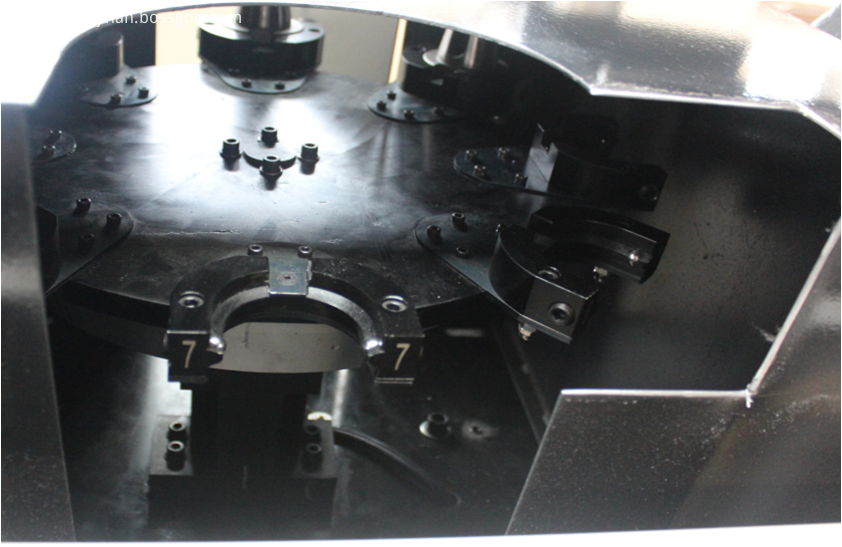

| Drill head quantity | One and ATC (8 pics tools) | One and ATC (8 pics tools) |

| Spindle motor power | 15Kw | 15Kw |

| Max drill diameter | Φ40mm | Φ40mm |

| Taper hole of spindle | BT40 | BT40 |

| Spindle speed | 30~3000r/min | 30~3000r/min |

| Spindle vertical stoke (Z axis) | 300mm | 300mm |

| Servo motor power of X axis | 2.0 kW | 2.0 kW |

| Servo motor power of Y axis | 1. 5 kW | 1. 5 kW |

| Servo motor power of Z axis | 2.0 kW | 2.0 kW |

| Motor power of scrap cleaner | 0.75 kW | 0.75 kW |

| Clamping type | 12 Hydraulic clams and T-slot | 12 Hydraulic clams and T-slot |

| Electric control type | SIEMENS 808D | SIEMENS 808D |

| CNC axis quantity | 3 | 3 |

| Position precision | ±0.08mm | ±0.08mm |

| With function of CAD/CAM automatic generation | ||

| With function of break point memory (Restart production easily after power off) | ||

| Overall size | About 4500x3900x3200 | About 4900x3900x3200mm |

| Weight | About 12000 | About 14000 |

ATC-Automatic Tool Change (8 pics tools)

Tools of this machine

Tapping

Chamfering

Our Service

The buyer should arrange no less than two people for accepting training. After training, the buyer should sign the "Receiving & Inspection Report" supplied by the seller to demonstrate the successful finish of commissioning and acceptance of the buyer.

FAQ

Q1. Are you a Manufacturer or a trading company?

A1.We are the manufacture, integrating with design, machining and assembling for angle machine.

Q2. Do you have stock product ready to deliver?

A2. In order to satisfy with the customer for fast delivery, we have certain amount of machines in stock, you can check the machine on LIVE-DEMONSTRATION at any time.

Q3. How do you deliver the finished products?

A3. The machine is mostly delivery by sea, rail way or road for some exception. For some urgent part or shipping document we delivered by air or Express like TNT, FEDEX,DHL,UPS,EMS, Etc.

Q4. How can you guarantee the after-sales service?

A4. We have the special after-sales service department, they will provide training program for operation and trouble shouting during installation. And they will visit the customer regularly for service.

all questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

Q5. What's delivery time for the angle machine.

A5. Within 20 days after payment.

Q6. How can you guarantee your finished angle machine quality?

A6. First, the machine will have 8 hours idle running;

Second, we will test the machine with the material working together.

Product Categories : Drilling Machine > Plate Drilling Machine